Foundry Tooling

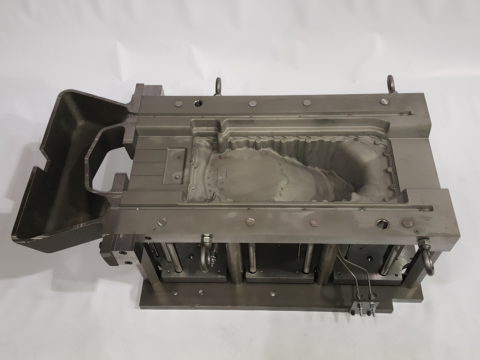

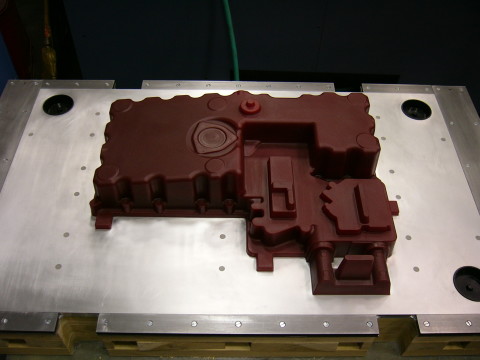

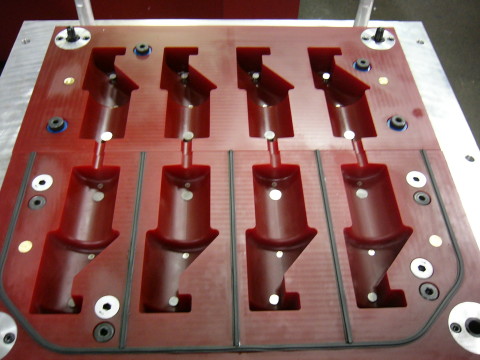

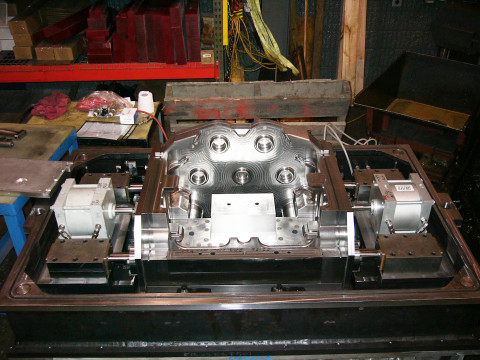

Zeman Tool engineers custom foundry tooling solutions or build customer designed tools. We build tooling for many types of casting processes. Zeman Tool accommodates single or multiple mold production.

Zeman produces foundry tooling out of various materials (steel, aluminum, urethane board, wood). Zeman’s range in tooling experience includes products from engine blocks and outboard motors to motorcycle clutch levers and large gears.